67 Power Wagon

Well-Known Member

Well its been a little since I've added any updates. Just a few "short" ones, but no less........"PROGRESS"!!!!!

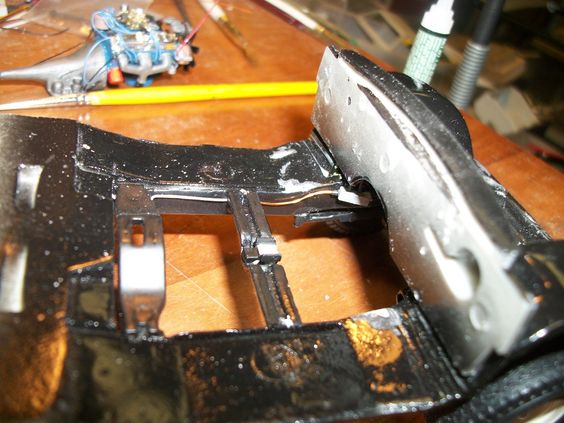

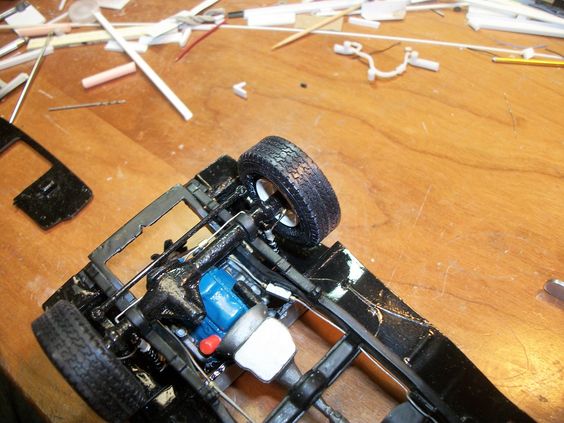

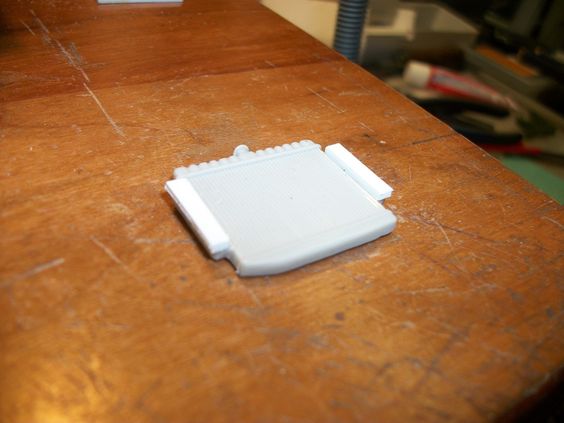

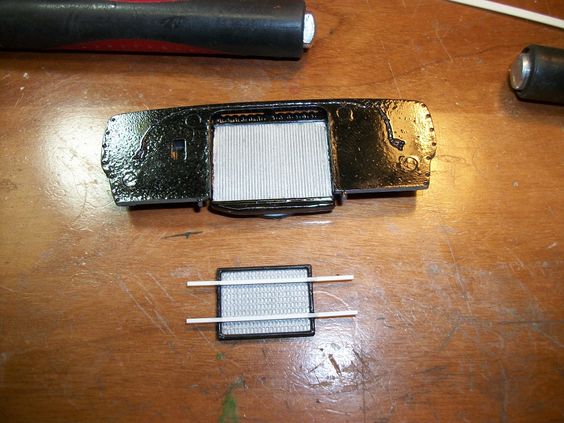

SO, As you guys know my last posting, I was working on making a removable spare tire mount. WELL, its done, and on the model! Took a bit to figure out how I was going to go about it! But, its in-place!

The "pole" was turned on the lathe as you know, but the ring base, was a part I had to drill out a center hole, and then pop the scrap through a hole punch to get the roundness of it, slightly filed the hole as the drill bit I used was undersized, so I could "fit" the part to the pole and then off to glue it to the frame as well as the pole with a good CA on the trucks frame (remember the frame is resin) and the pole is styrene! SO, once the frame CA dried, I glued the ring to the pole with Tenax 7R!

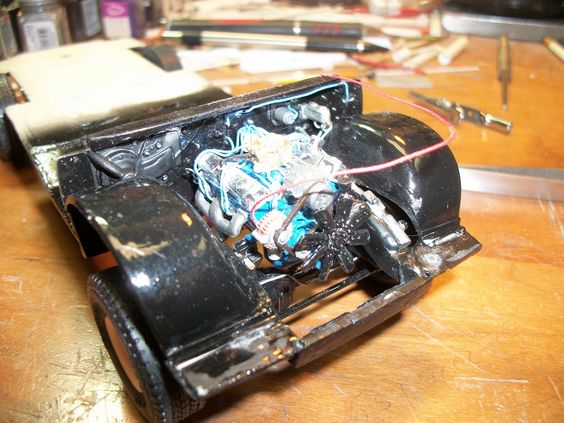

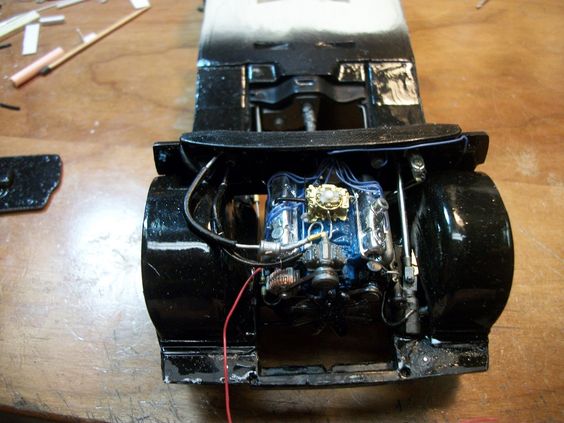

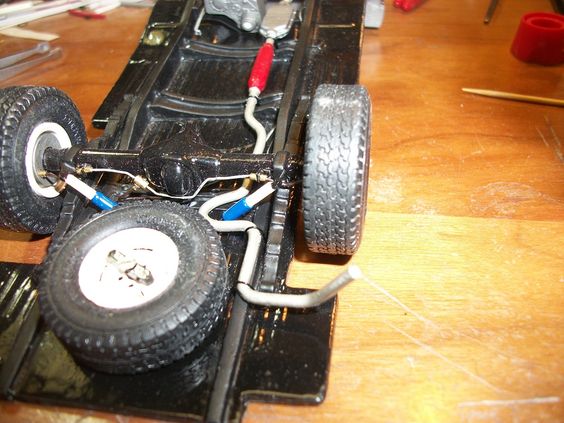

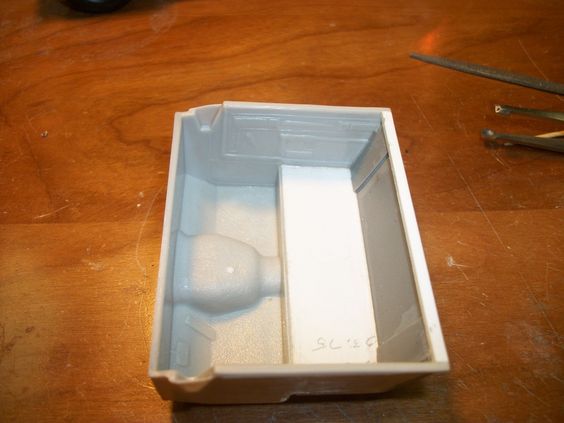

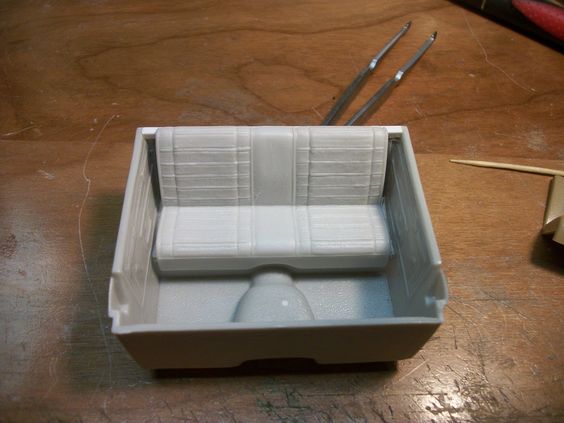

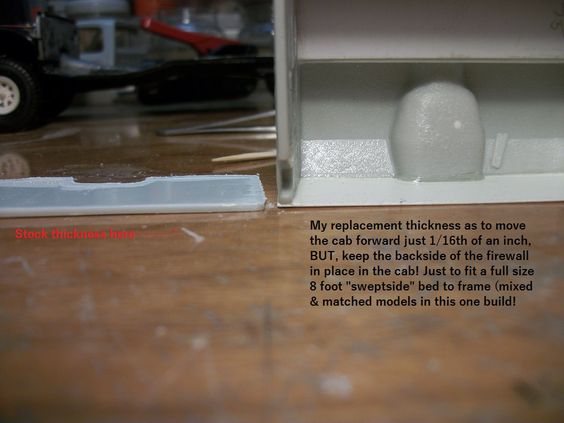

Then while that was sitting and drying, I worked on the firewall. Now this was FUN, as I had to make an identical copy of the one I made in my truck (in real life, on the 2 trucks, they would have been VERY close the same!) SO, I had to take my Power Wagon truck, and literally "copy" it, a second time!

That looks pretty good (There is ONE, difference!) I had thought my Dad, (being "Dad") and thinking, I knew him, and I did....... BUT, in normal things with him, he would HAVE removed the A/C, for the power consumption it used. BUT to hear my uncle, he tells me Dad NEVER did it on this truck! Which, surprised me to hear, as I know for a fact this was one of VERY FEW that Dad didn't remove the A/C compressor from! SO, with the firewall detail, I'll be adding the heater core hoses and fittings (like I did on my truck, BUT I'll also be adding the A/C piping too, that runs from the compressor to the firewall! (Meaning, I'll have running pipe from the front of the compressor to a condensing radiator near the standard radiator!) SO, a little "extra" detail being added over-all, BUT the extra fittings to the firewall as well and I have yet to add them!

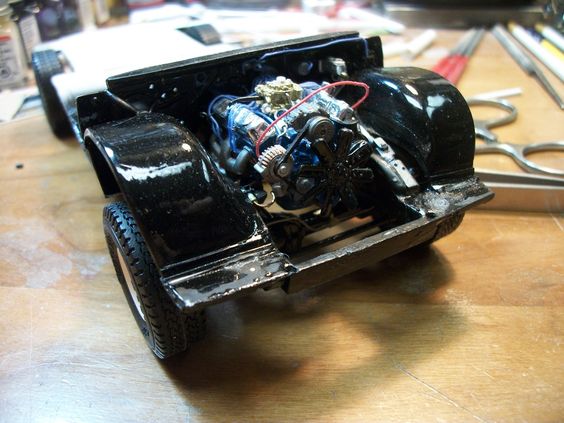

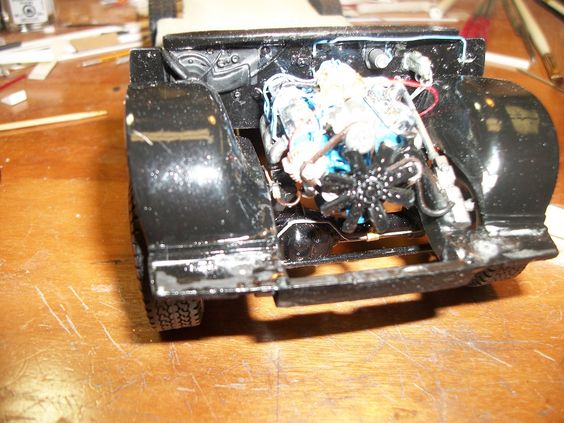

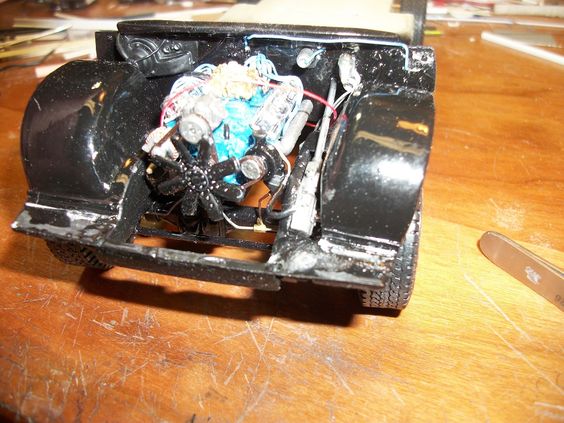

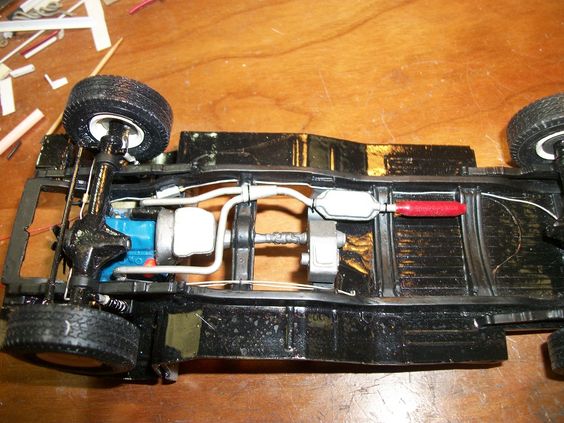

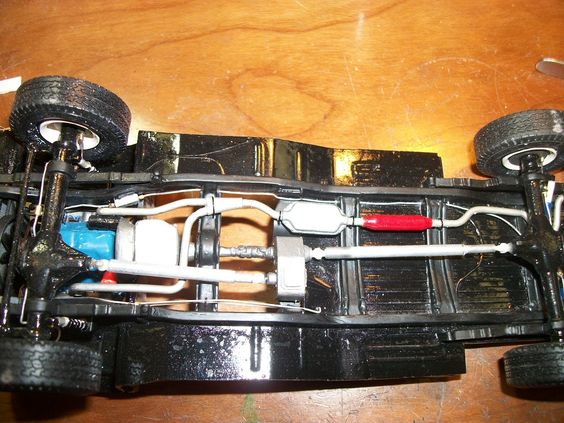

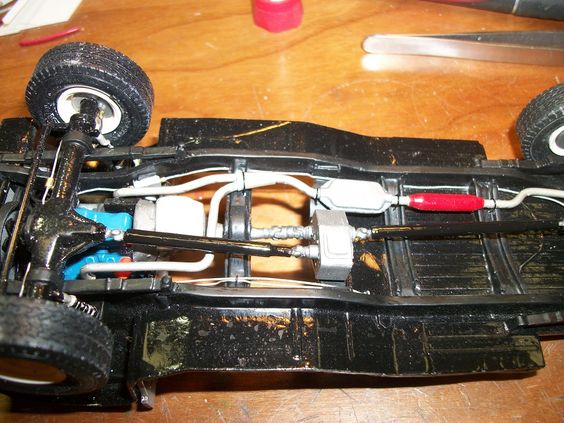

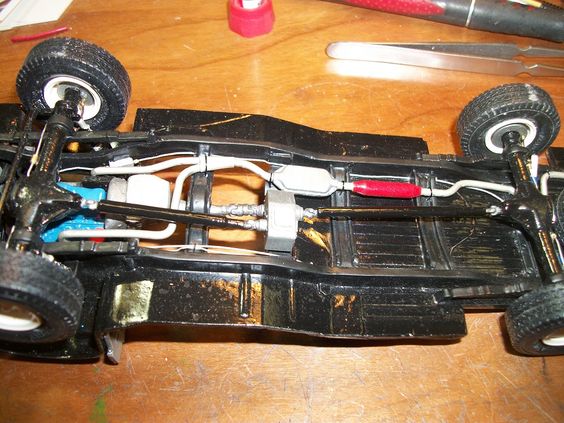

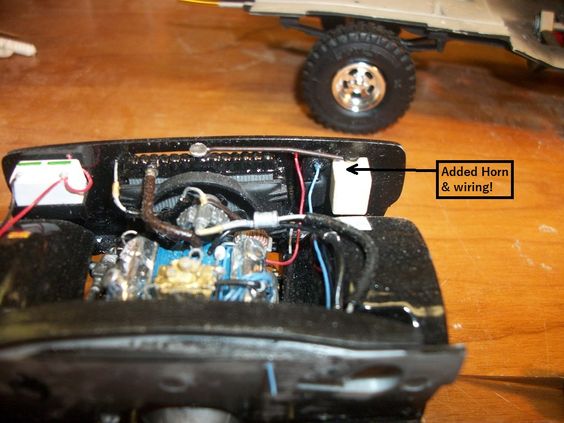

So, while some of the paint was drying,and CA drying from the added wiring to the firewall. I got to working on the belt set up on the engine, A/C compressor added, as well as the power steering, and alternator. This all looks GREAT! Alternator is painted so, the internal wires are seen between the cooling ribs of its casing, as well as "drilled" for the wires that lead off of it, just as I did on my Power Wagon model. The blue wire runs to the coil, and back to the firewall. The red wire on the alternator runs to the battery, and across the radiator core support. (I have to get that all detailed up pretty soon too!)

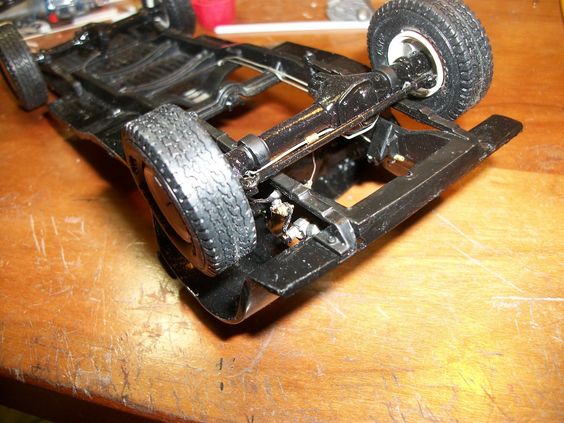

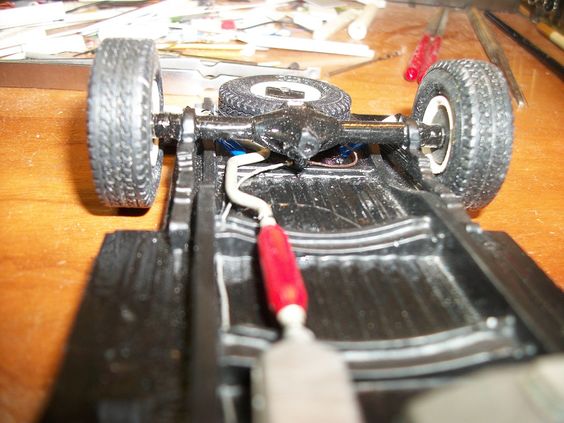

-and now to top it all off, I'm working on adding valve stems to the rims on Dads truck! I haven't yet gotten pics of that yet, BUT, they are drilled for them, and 2 or 3 have them in place! -Thought I'd let everyone know, I did choose to add them, as I said, they are drilled with having the hole smaller to "press fit" the valve stem, and because on Dads truck the tires are solid vinyl, I drill partly into them and press the wire "valve stem" into the vinyl to "grab" and hold in place without glue!

More to come as progress happens! -Enjoy!

SO, As you guys know my last posting, I was working on making a removable spare tire mount. WELL, its done, and on the model! Took a bit to figure out how I was going to go about it! But, its in-place!

The "pole" was turned on the lathe as you know, but the ring base, was a part I had to drill out a center hole, and then pop the scrap through a hole punch to get the roundness of it, slightly filed the hole as the drill bit I used was undersized, so I could "fit" the part to the pole and then off to glue it to the frame as well as the pole with a good CA on the trucks frame (remember the frame is resin) and the pole is styrene! SO, once the frame CA dried, I glued the ring to the pole with Tenax 7R!

Then while that was sitting and drying, I worked on the firewall. Now this was FUN, as I had to make an identical copy of the one I made in my truck (in real life, on the 2 trucks, they would have been VERY close the same!) SO, I had to take my Power Wagon truck, and literally "copy" it, a second time!

That looks pretty good (There is ONE, difference!) I had thought my Dad, (being "Dad") and thinking, I knew him, and I did....... BUT, in normal things with him, he would HAVE removed the A/C, for the power consumption it used. BUT to hear my uncle, he tells me Dad NEVER did it on this truck! Which, surprised me to hear, as I know for a fact this was one of VERY FEW that Dad didn't remove the A/C compressor from! SO, with the firewall detail, I'll be adding the heater core hoses and fittings (like I did on my truck, BUT I'll also be adding the A/C piping too, that runs from the compressor to the firewall! (Meaning, I'll have running pipe from the front of the compressor to a condensing radiator near the standard radiator!) SO, a little "extra" detail being added over-all, BUT the extra fittings to the firewall as well and I have yet to add them!

So, while some of the paint was drying,and CA drying from the added wiring to the firewall. I got to working on the belt set up on the engine, A/C compressor added, as well as the power steering, and alternator. This all looks GREAT! Alternator is painted so, the internal wires are seen between the cooling ribs of its casing, as well as "drilled" for the wires that lead off of it, just as I did on my Power Wagon model. The blue wire runs to the coil, and back to the firewall. The red wire on the alternator runs to the battery, and across the radiator core support. (I have to get that all detailed up pretty soon too!)

-and now to top it all off, I'm working on adding valve stems to the rims on Dads truck! I haven't yet gotten pics of that yet, BUT, they are drilled for them, and 2 or 3 have them in place! -Thought I'd let everyone know, I did choose to add them, as I said, they are drilled with having the hole smaller to "press fit" the valve stem, and because on Dads truck the tires are solid vinyl, I drill partly into them and press the wire "valve stem" into the vinyl to "grab" and hold in place without glue!

More to come as progress happens! -Enjoy!