67 Power Wagon

Well-Known Member

SO, with the weather being NIICE out its been difficult getting "A LOT" done on any modeling but I did manage a little bit.....

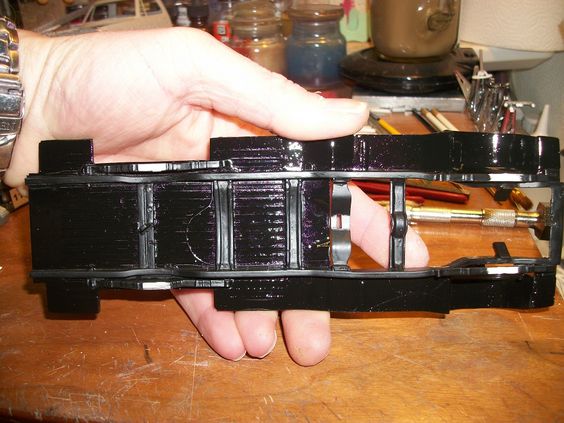

I got to looking at that old Donor frame, that I'm trying to save as its styrene for my Railroad truck build as I'll be doing extensive frame work to it for that model, BUT I was more interested in the suspension to go under my Dads '79 Adventurer 150...... SO, I seen that the crude steering details they at MPC made way back when, it was good for the time back then, BUT, I thought I could improve upon it....

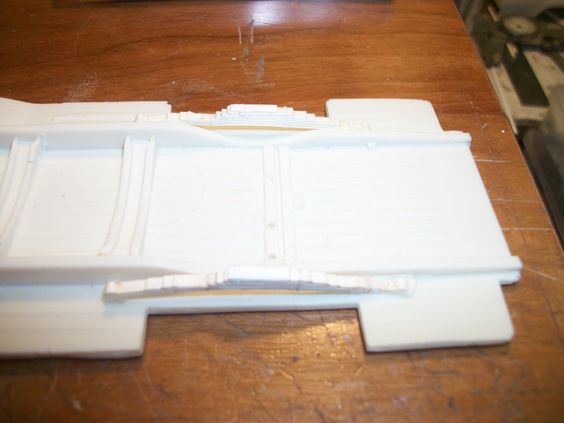

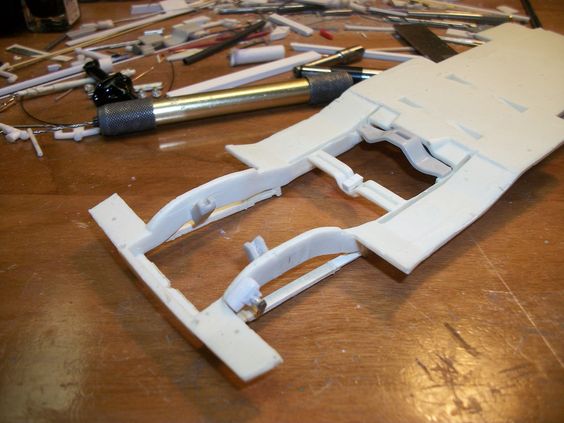

Went from this:

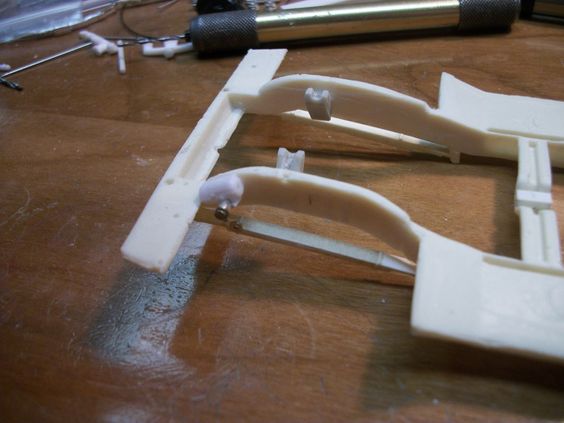

Removed from the styrene frame.....

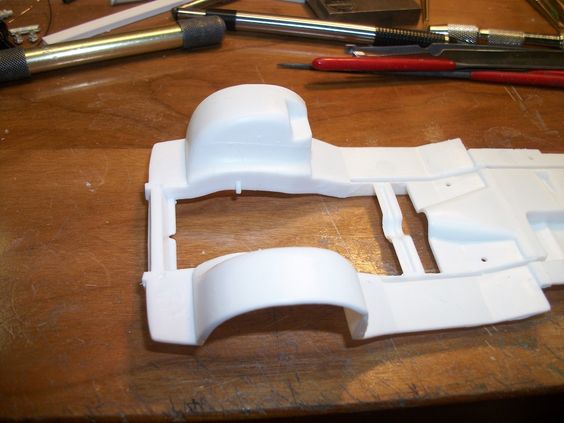

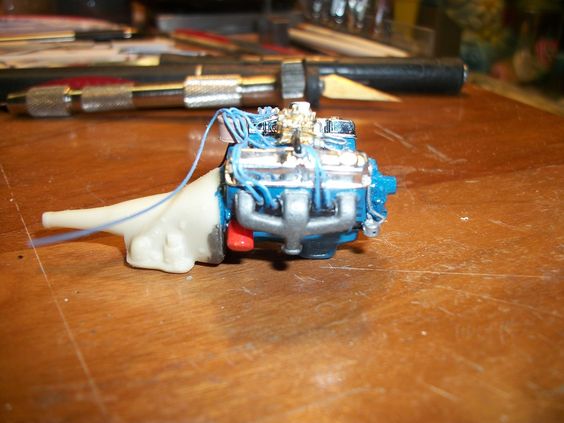

Better view as the part itself. I think that steering tie-rod, could be improved in detailing so, I went on to do a bit more then just replace the missing "rod" MPC had originally with the part.

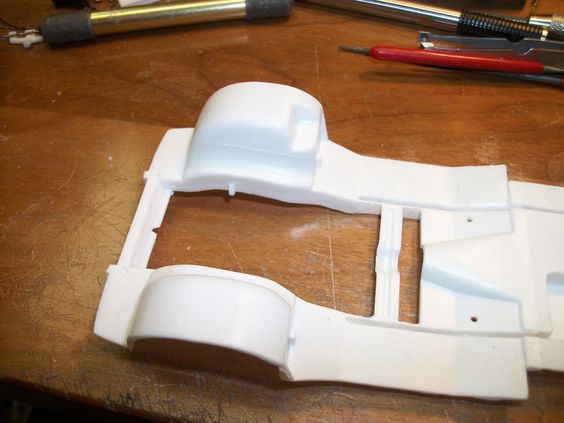

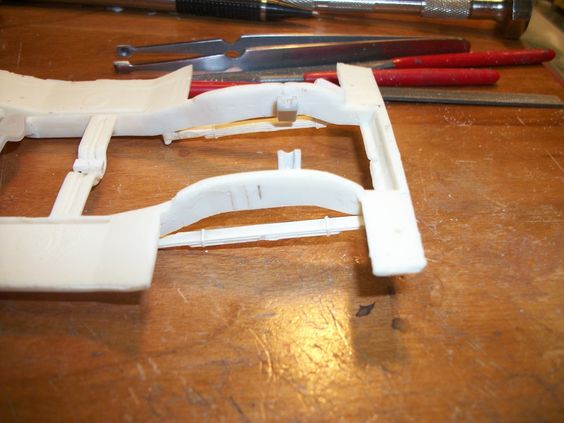

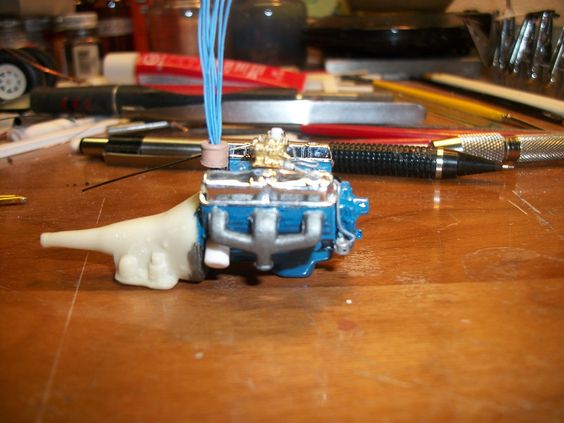

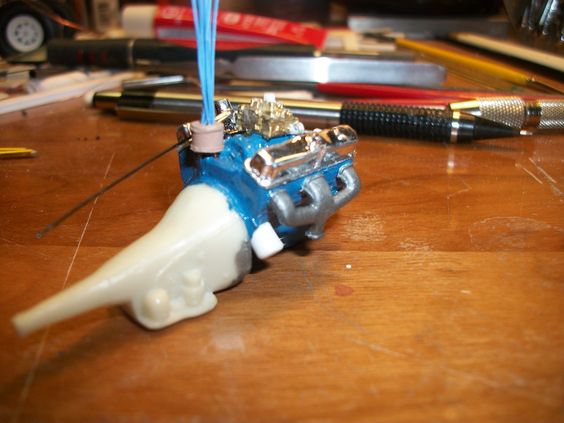

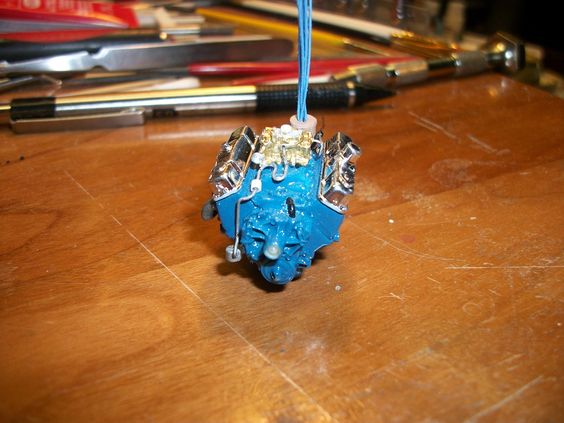

Heres what I made it to be:

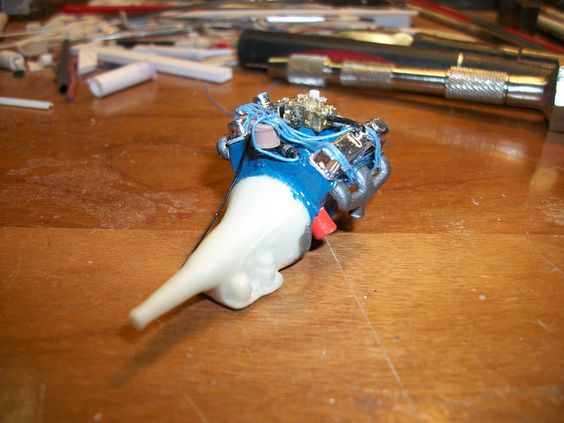

Right side up, removed from the leaf springs, for detailing and height adjustment. I also added the drag link that would connect to anther rod that goes to the power steering, this detail wasn't even one the model, I made it myself, and added it from pictures of a real Dodge Adventurer truck! -It is a bit different from what I had in my Power Wagon! I knew there would be differences, BUT I tell you all, theres a bit more building these 2 trucks then I ever thought in the beginning, more then just the exterior, and interior...... AND even the motors!

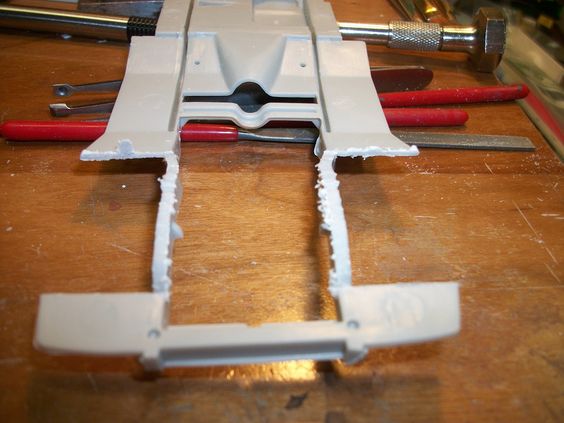

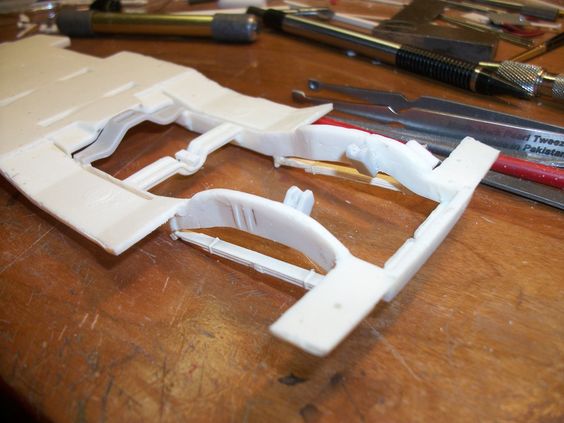

Notice, I removed a bit out of the mount where the rear mounts to the leaf springs! to lower the stance a bit, as my Dads real truck didn't appear "lifted" and left this part of the model alone, it would have made the truck look "lifted" BUT, it also wasn't "lowered" either, altho, thats what I've sort of done here, is lowered the trucks frame and body over the tires.... NOT a "low Rider" but more of a family truck sort of height!

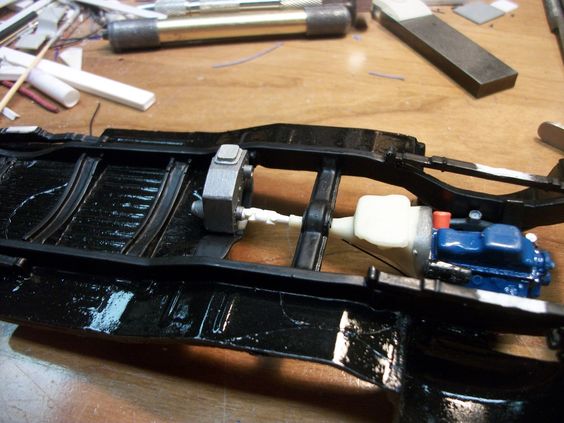

Same front axle, flipped over looking at the bottom! I got to paint this thing an getting it ready BUT I may as well get as much detail on it as I can before it gets painted!

More to follow right after these short messages! ENJOY!

I got to looking at that old Donor frame, that I'm trying to save as its styrene for my Railroad truck build as I'll be doing extensive frame work to it for that model, BUT I was more interested in the suspension to go under my Dads '79 Adventurer 150...... SO, I seen that the crude steering details they at MPC made way back when, it was good for the time back then, BUT, I thought I could improve upon it....

Went from this:

Removed from the styrene frame.....

Better view as the part itself. I think that steering tie-rod, could be improved in detailing so, I went on to do a bit more then just replace the missing "rod" MPC had originally with the part.

Heres what I made it to be:

Right side up, removed from the leaf springs, for detailing and height adjustment. I also added the drag link that would connect to anther rod that goes to the power steering, this detail wasn't even one the model, I made it myself, and added it from pictures of a real Dodge Adventurer truck! -It is a bit different from what I had in my Power Wagon! I knew there would be differences, BUT I tell you all, theres a bit more building these 2 trucks then I ever thought in the beginning, more then just the exterior, and interior...... AND even the motors!

Notice, I removed a bit out of the mount where the rear mounts to the leaf springs! to lower the stance a bit, as my Dads real truck didn't appear "lifted" and left this part of the model alone, it would have made the truck look "lifted" BUT, it also wasn't "lowered" either, altho, thats what I've sort of done here, is lowered the trucks frame and body over the tires.... NOT a "low Rider" but more of a family truck sort of height!

Same front axle, flipped over looking at the bottom! I got to paint this thing an getting it ready BUT I may as well get as much detail on it as I can before it gets painted!

More to follow right after these short messages! ENJOY!