You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reviving an 87 D150

- Thread starter Gustav

- Start date

Gustav

Active Member

Well, she runs!

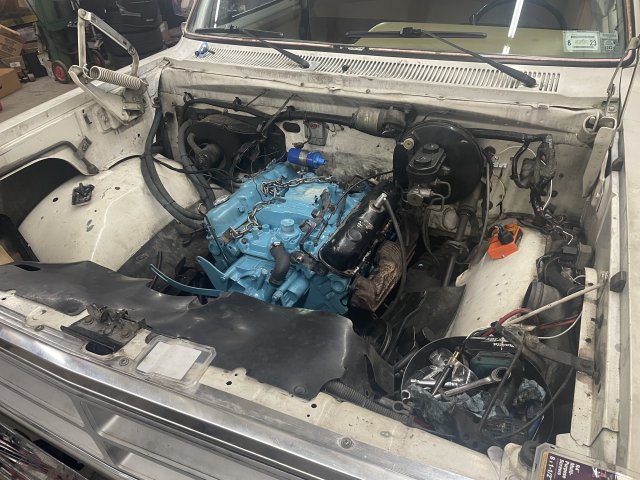

This weekend i had the chance to work in my buddy's shop and we got the old engine pulled, and the new one put in. We figured out what was wrong with the first one as well (besides a cracked coolant passage in the head) - the oil pump shattered where it meets with the distributor drive gear. Either I neglected to tighten down those two bolts enough, or they had worked themselves loose enough that the hex end and socket got out of alignment. The pump still spins fine, it's just that connection went bye bye. So that was my bad, either way. I'll never make that mistake again!

But overall, it feels good to have a better, more thoroughly rebuilt motor in the truck now. After I finished building it, all accessories, etc, we measured 70lbs of oil pressure cold, which is great.

We figured out that this blue one is actually a 1970 block, even though it apparently came out of a 1979 van. Swapping wasn't too bad, just 18 hrs for the full maneuver. The torque converter and shaft seal on the transmission both looked like they had been replaced at some point - both super clean.

Got it running, though am chasing some serious vacuum leaks. The intake is a spread bore, and the carb is a square bore (rookie mistake), so perhaps that's the issue. I have a simple plate adapter in there, but maybe that seal isn't good enough. But it runs! Coolant temps are good, after replacing the thermostat and adding a little hole to it, and the transmission leaks like a sieve, but dang it feels good to drive the truck home, and have it back in the driveway.

The new engine is very responsive, sounds great, no ticks or anything. The left bank exhaust is still smoking, but I think that's just accumulated coolant from the last engine getting burned off. It seems to be calming down after a short drive or two.

I already found a use for it - hauling the old engine. I assume the crank would need to be machined to be usable again, along with the rod bearings, but maybe I'll save portions of it? Not sure I have room or capacity to store all of that, but maybe. The block should be salvageable, but also very scrappable. And one head has a crack in the coolant passages. Any suggestions on what to do with it?

Still need to get some small stuff done with it, but it's a huge milestone - I've had this thing for 2 years, and it finally feels like it might actually be usable now. Fingers crossed. I'll post some more photos of the final swapped engine soon. Time to put my feet up.

This weekend i had the chance to work in my buddy's shop and we got the old engine pulled, and the new one put in. We figured out what was wrong with the first one as well (besides a cracked coolant passage in the head) - the oil pump shattered where it meets with the distributor drive gear. Either I neglected to tighten down those two bolts enough, or they had worked themselves loose enough that the hex end and socket got out of alignment. The pump still spins fine, it's just that connection went bye bye. So that was my bad, either way. I'll never make that mistake again!

But overall, it feels good to have a better, more thoroughly rebuilt motor in the truck now. After I finished building it, all accessories, etc, we measured 70lbs of oil pressure cold, which is great.

We figured out that this blue one is actually a 1970 block, even though it apparently came out of a 1979 van. Swapping wasn't too bad, just 18 hrs for the full maneuver. The torque converter and shaft seal on the transmission both looked like they had been replaced at some point - both super clean.

Got it running, though am chasing some serious vacuum leaks. The intake is a spread bore, and the carb is a square bore (rookie mistake), so perhaps that's the issue. I have a simple plate adapter in there, but maybe that seal isn't good enough. But it runs! Coolant temps are good, after replacing the thermostat and adding a little hole to it, and the transmission leaks like a sieve, but dang it feels good to drive the truck home, and have it back in the driveway.

The new engine is very responsive, sounds great, no ticks or anything. The left bank exhaust is still smoking, but I think that's just accumulated coolant from the last engine getting burned off. It seems to be calming down after a short drive or two.

I already found a use for it - hauling the old engine. I assume the crank would need to be machined to be usable again, along with the rod bearings, but maybe I'll save portions of it? Not sure I have room or capacity to store all of that, but maybe. The block should be salvageable, but also very scrappable. And one head has a crack in the coolant passages. Any suggestions on what to do with it?

Still need to get some small stuff done with it, but it's a huge milestone - I've had this thing for 2 years, and it finally feels like it might actually be usable now. Fingers crossed. I'll post some more photos of the final swapped engine soon. Time to put my feet up.

65 sporty

Well-Known Member

The cracked head is a core, the other head can be rebuilt or also a core for a reman head, the crank can be turned or a core for a reman crank. The rods can be resized, but usually if a bearing has spun it's 50/50 for the rod and the block can be machined as you know.

Gustav

Active Member

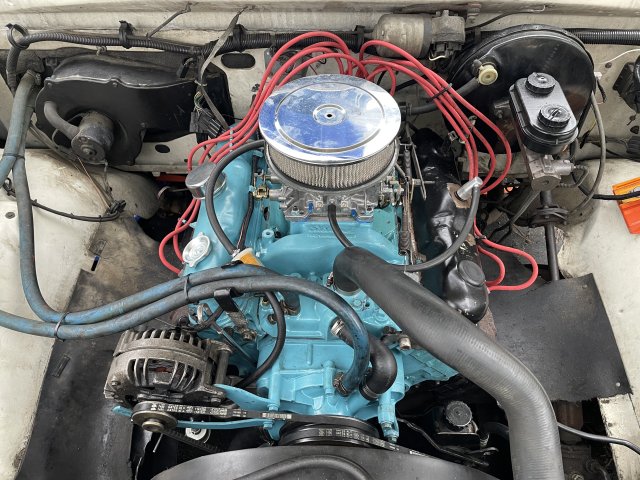

A couple shots of the engine fully installed. I think it all came together well! Been driving the truck a little bit, and it feels pretty good.

My heater core sprung a leak immediately, so that's on order, along with various other little parts to finish up the mechanical things. I need to make or have a new exhaust system made for it - the previous owner had some terrible cob-job installed on the outside of the frame rails that rattles and knocks like crazy, no flex pipe or catalysts, etc.

So the work continues. But I am praying that this motor will stay in (mostly) one piece in 2023.

Happy New Year, folks.

My heater core sprung a leak immediately, so that's on order, along with various other little parts to finish up the mechanical things. I need to make or have a new exhaust system made for it - the previous owner had some terrible cob-job installed on the outside of the frame rails that rattles and knocks like crazy, no flex pipe or catalysts, etc.

So the work continues. But I am praying that this motor will stay in (mostly) one piece in 2023.

Happy New Year, folks.

Gustav

Active Member

Been driving the truck around quite a bit and loving it. It's been doing pretty well.

Some transmission issues to solve: it shifts well from 1-2, then slips immediately into 3rd. If I manually shift, it holds the gear just fine. I know next to nothing about automatics - is that a valve body thing? I know I need to replace the trans pan gasket on it, and will do the filter at the same time, but does anyone know if there anything I should be looking for specifically while the bottom is off of it?

I just replaced the heater core - it was leaking reaaaal bad.

Getting it out wasn't too hard - just had to remove the ash tray and glove box, loosen up the mounts for the dashboard on the passenger side, and be real persuasive.

I cleaned up and re-used the heavyweight rubber gasket that surrounds the core, seems like a better solution than the thin foam the new core came with. Looking forward to having heat, and a dry interior! haha

Some transmission issues to solve: it shifts well from 1-2, then slips immediately into 3rd. If I manually shift, it holds the gear just fine. I know next to nothing about automatics - is that a valve body thing? I know I need to replace the trans pan gasket on it, and will do the filter at the same time, but does anyone know if there anything I should be looking for specifically while the bottom is off of it?

I just replaced the heater core - it was leaking reaaaal bad.

Getting it out wasn't too hard - just had to remove the ash tray and glove box, loosen up the mounts for the dashboard on the passenger side, and be real persuasive.

I cleaned up and re-used the heavyweight rubber gasket that surrounds the core, seems like a better solution than the thin foam the new core came with. Looking forward to having heat, and a dry interior! haha

7mopar

Well-Known Member

While you had the trans pan off check the bands. But they should be fine if you have R & 1-2. D requires clutch pack. So check for gritty particles in the trans fluid. Sure sounds like a front clutch problem. If you have a transmission shop close people trust they can test it in the truck.

But really lock for those gritty particles and shinny stuff in the pan and the drained fluid.

But really lock for those gritty particles and shinny stuff in the pan and the drained fluid.

I'm just now in the process of acquiring parts and pulling the dash out of my 85 to convert it from factory non ac to factory ac .... currently just short a couple of parts. I have 3 factory ac heater plenum boxes from 80s dodge trucks, one is definitely parts only/because the housing is bad/I found a place that sells all the pre cut seals and weatherstrip for the heater box, and bought a set. I have a brand new (reman) compressor, new lines, just missing a couple of parts. I'm hoping to have at least 1 good heater core and evaporator among the 3 heater boxes that I have, also have all the vents and ductwork I'm gonna need, 2 factory ac dashes ( hope to be able to just cut the holes for the vents into my original dash since the vin for this truck is riveted to the dash)

Still need the cut out switches, the expansion valve and a condenser. I might have a good used condenser, have to look. I know I should go new on that but this isn't meant to be a year round daily driver, only in the warm, non road salt months

Still need the cut out switches, the expansion valve and a condenser. I might have a good used condenser, have to look. I know I should go new on that but this isn't meant to be a year round daily driver, only in the warm, non road salt months

Gustav

Active Member

I finally replaced the wheels on the truck - went from the Foose 5 spokes, staggered 17/18 setup on 40-series tires, to American Racing 17s all around, with 55 series tires. The difference is immense. It drives so much better now, and I think they look better, too. Figured I'd share a couple photos! And I took the truck to its first show - "MOPARS at the Valley" at Lebanon Valley Speedway. Some really great cars and trucks on display there (including a couple here)

Gustav

Active Member

Oh, and I replaced the trans pan gasket, filter, and cooler lines last month. Nothing horrible in the pan or on the magnet. I adjusted the kickdown linkage more and its shifting really nicely now -- and no more leaks. Feels good.

7mopar

Well-Known Member

Those 17's look pretty good on there. How tall are the rear tires?

Oldest son went with 40 series to get the tread wanted. Now the ties are to short. Finding performance tires in 17 can be a problem.

Oldest son went with 40 series to get the tread wanted. Now the ties are to short. Finding performance tires in 17 can be a problem.

Gustav

Active Member

The wheels are 17x8 with a 0 offset, and tires all around are Vredestein 235/55 R-17. These definitely aren't performance tires, but look nice, have an XL rating, and compliant ride. I shopped around on discount tire direct and tire rack, and tried a variety of tire sizes to find the right one. Also really useful to use is this wheel and tire calculator: www.wheel-size.com/calc/

paul massaro

pomonamissel

working on my 88 d150 , made up some old school rims for it , had to do some machining to the rims so they could fit over those giant centering hubs and had to turn down the bearing nose some on the rotors so there could clear the cone of the rims , 200s's is what i'm going with 8 1/2's on the rears with 275/60-15 bf t/a's and 7's up front with 235/70-15's bf t/a's . still working on the body and paint but i'm not sure i'll leave that 318 / 999 in it . would love to do a modern 5.7 or 6.1 hemi with a 8hp trans in it . but i might just put a 340 / 727 in it because i've got it .

7mopar

Well-Known Member

Going to 5 on 4-1/2 and the old school wheels would have fit. Of course you would have had to have gone back a few years to find the parts. No machining would have been required.

paul massaro

pomonamissel

the machining cost was just time on the lathe , didn't buy a thing . and the rims were in 5 on 5 1/2 bc , a set i collected for a ford p/u . but never used .

7mopar

Well-Known Member

How big is your lathe anyway?the machining cost was just time on the lathe , didn't buy a thing . and the rims were in 5 on 5 1/2 bc , a set i collected for a ford p/u . but never used .

paul massaro

pomonamissel

well we can swing a 15'' rim without issues . i have a bigger swing lathe but i need a compound and tool holder for , it's a leblond 19'' swing i believe .

I just picked up a set of old school Mickey Thompson classic aluminum, 15 x8’s for the 93. About 45 minutes each, to polish, ordered new center caps and black lug nuts. I’ve been looking for a factory aluminum set, but couldn’t find any in decent shape. Gonna get them mounted up today. I like the old school look, on the old school vehicles. I’ve got 15” centerlines on the 72 Plymouth.

Last edited: