63fordturbo

Member

Finally bit the bullet and started doing a disc brake swap on my truck as I had an axle seal leaking and twisting axles. Also I wanted to do things a bit out of the norm. It's who I am to prove people wrong. Haha! I wanted to install a big brake set up on the rear of my '63 Unibody.

I have 11" rotors with '70 chevelle calipers on the front and thought I'd go with 13" rotors off the front of a 2004 RAM 1500 with a bracket/caliper setup off a Lincoln Versailles. Ran into just a few issues and thought I'd put them up on here...

First was the RAM rotors had the same bolt pattern (5 X 5 1/2") however use a much larger wheel stud and axle flange. So I machined (with the help of a good friend Greg Peterson) a set of spacers to fill the gap between the rotor and studs. Then Greg the perfectionist he is came up with the idea to fix the floating wheel adapter issue since I actually like to USE my truck. What a concept! And make a billet aluminum center support to take up the gap of the rotor to axle flange gap, center the wheel adapter then get sandwiched in with the wheel... Here are some pics...

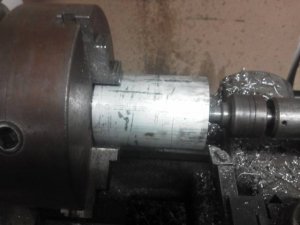

Milled it down, drilled out the center for the stud to rotor gap.

Cut them off in the band saw at .250"

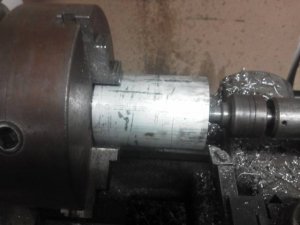

Started with 3 3/8" aluminum bar stock

First cut was to fit wheel adapter/rotor

Second cut was to recess into wheel

Third was to cut off the excess.

Fourth milled out the center to countersink over the axle flange.

Heres a back pic of where it will take up the gap between the rotor to axle flange.

I have 11" rotors with '70 chevelle calipers on the front and thought I'd go with 13" rotors off the front of a 2004 RAM 1500 with a bracket/caliper setup off a Lincoln Versailles. Ran into just a few issues and thought I'd put them up on here...

First was the RAM rotors had the same bolt pattern (5 X 5 1/2") however use a much larger wheel stud and axle flange. So I machined (with the help of a good friend Greg Peterson) a set of spacers to fill the gap between the rotor and studs. Then Greg the perfectionist he is came up with the idea to fix the floating wheel adapter issue since I actually like to USE my truck. What a concept! And make a billet aluminum center support to take up the gap of the rotor to axle flange gap, center the wheel adapter then get sandwiched in with the wheel... Here are some pics...

Milled it down, drilled out the center for the stud to rotor gap.

Cut them off in the band saw at .250"

Started with 3 3/8" aluminum bar stock

First cut was to fit wheel adapter/rotor

Second cut was to recess into wheel

Third was to cut off the excess.

Fourth milled out the center to countersink over the axle flange.

Heres a back pic of where it will take up the gap between the rotor to axle flange.

Last edited: