Black-Chev-K

New Member

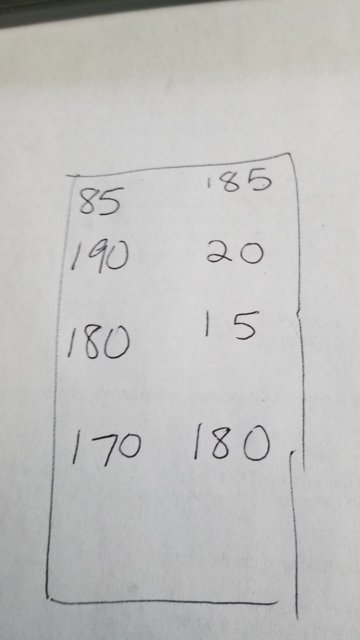

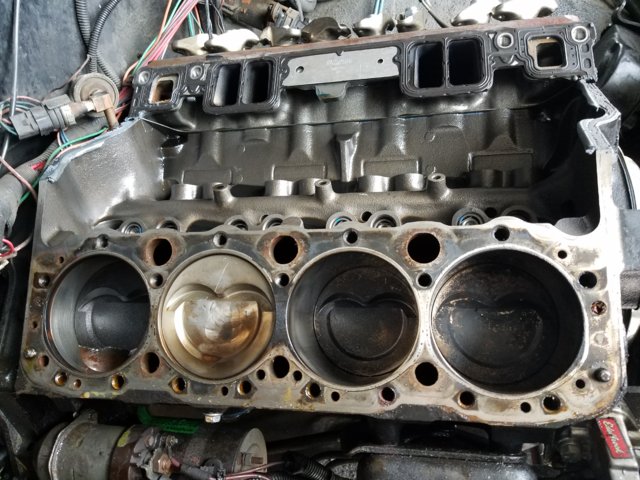

I've got a Blueprint 3830CTC1 (w/Edelbrock carb & cast iron heads) (405 HP, 440 torque) in an 86 Chevy K-series pickup with 5300 miles on the engine. Truck has an automatic transmission with 35 inch tires and 4.56 gears. Engine has always run good, especially the top end - even though it is anything but aerodynamic. In November, after warming up, I pulled slowly out of the garage and heard a loud pop. ...couldn't imagine what it was, so I got out and looked around the truck and didn't notice anything abnormal. When driving down the road, there was a notable loss of power to the point I knew something was wrong. In running a compression check (see attached), I found cylinders 4 & 6 to have almost nothing. ...took the head off the passenger side and found a huge chunk blown out of the head gasket between those 2 cylinders. Head bolts were pretty loose. See attached pictures of head gasket and top of block on the passenger side. In talking to Blueprint engines and showing them, they think that it was a detonation issue; they said it was timing and those cylinders were running too hot. I always run the highest octane available when fueling. I took head gasket and pictures to local shop where I have a trusted mechanic for many years. From looking at the gasket and its seal that doesn't appear completely compressed, he thought the head was never torqued down. Others that have seen it thought the same thing. Blueprint said that it is completely normal for the head bolts to be loose after a blown head gasket, but I'm getting varying opinions on this. Straight edge seems to indicate head and top of block surface are good. My main concern is to try to understand what happened in order to determine if I can put things back together and have everything be OK. Blueprint said to reuse existing head bolts, install new head gasket, & reconnect distributor without the vacuum advance connected, and everything should be good. Would you use any gasket sealer or locktite to prevent the head bolts from backing out? Any ideas, thoughts, takes...?