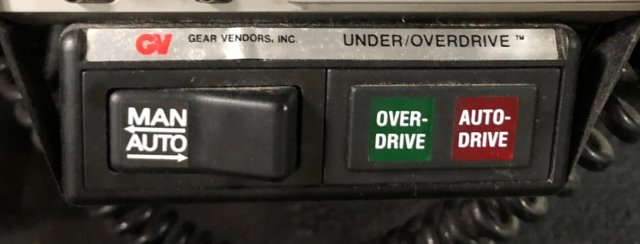

Next up, I got rid of the Big Gear Vendors Control Box. The system is now defaulted to Manual control since I really don't need Auto with a Diesel... I replaced the big Red & Green indicators with panel mounted Red & Green LED's in the dash, just to the right of the climate controls... so now all I have is the system activation switch on the floor (old dimmer switch), and the two LED's in the dash.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st Diesel - 1st Post

- Thread starter 67Mopar

- Start date

Time for new fancy steering wheel.

I Picked up a new steering wheel for Montana from the folks over at Forever Sharp. https://fssteeringwheels.com/ Nice quality and 1st rate Customer Service.

My wife likes it, she thinks I should buy another one just like it for the 67 Charger, but I already have a nice wheel for that application. I think this one looks good in the old 90 W250 Diesel

I Picked up a new steering wheel for Montana from the folks over at Forever Sharp. https://fssteeringwheels.com/ Nice quality and 1st rate Customer Service.

My wife likes it, she thinks I should buy another one just like it for the 67 Charger, but I already have a nice wheel for that application. I think this one looks good in the old 90 W250 Diesel

7mopar

Well-Known Member

Looking good. How hard were the LEDs to put in the dash?

65 sporty

Well-Known Member

Thanks for the updates. You have been busy.

Thanks Fella's!

Quick and easy swap... The only thing you have to watch out for and remember here is that LED's are Polarity Sensitive. On top of that... in most cases the LEDS are not marked +/- so you have to test them before installing them. No big deal of course, but many folks forget and get it wrong the first time. Then they suddenly remember... oh yeah... Crap... Now I have to take it apart again.

How hard were the LEDs to put in the dash?

Quick and easy swap... The only thing you have to watch out for and remember here is that LED's are Polarity Sensitive. On top of that... in most cases the LEDS are not marked +/- so you have to test them before installing them. No big deal of course, but many folks forget and get it wrong the first time. Then they suddenly remember... oh yeah... Crap... Now I have to take it apart again.

LocuMob

Fluid Technician

Wow, lots of work done! Looks good.

multimopes

Well-Known Member

Belated welcome aboard. Beautiful truck and excellent work. I wasn't paying attention to the date of your submittals and was thinking you must not get much sleep with the amount of progress you made. Excellent!

If there's one thing these old Diesels are famous for, it's their ravenous appetite for Voltage Regulators! They just can't get enough, they're never satisfied.

Well, I can't afford keep replacing VR's every other thing, so I had to do something about this little problem.

As I suspected, there were so many shorts and bad connections in old the electrical system, due to old dirty connections & connectors, that it was reducing the voltage to the VR, causing it to remain in an active state all the time, which is why the cheap over the counter units were frying on a fairly frequent basis. Even a heavy duty Transpo unit held out for as long as it could, but eventually lost the battle.

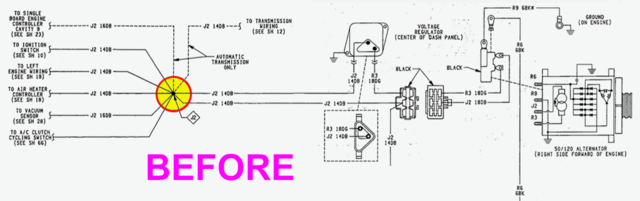

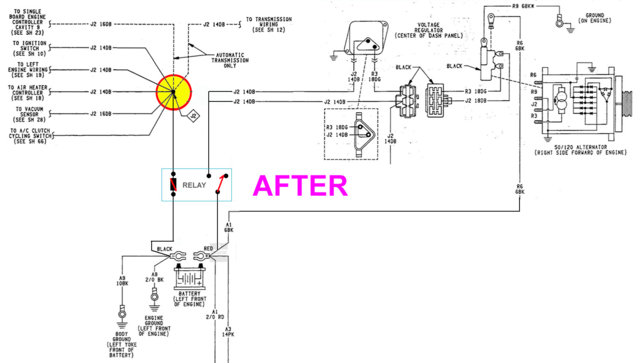

That said, I decided to install a Relay in the system that would relocate the voltage sensing circuit of the VR from the weak (under voltage) ignition circuit, and move it directly to the Battery.

To do this I had to locate the main ignition circuit splice in the wiring harness. Then locate and separate the two required charging circuit wires from the splice, and wire them to the relay as illustrated below. I ran the wires through the wiring harness to keep it neat. Then I ran a seperate hot and ground from the relay to the battery. Problem solved...

The gage for the Charging System holds steady at dead center now. This is the first time since I've owned the truck that the gage has read correctly. Previously it had always leaned more to the charging side, sometimes more than others, but always to the charging side. As you might expect, the battery would often get quite warm as well.

I eventually got in there and took care of all those pesky electrical connections that were drawing down on the system, and causing erratic behavior issues, so that's all good to go now as well.

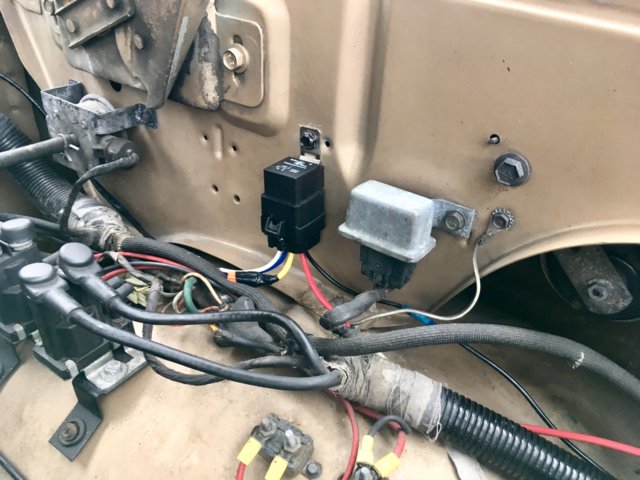

I also relocated my VR from the OEM Death Valley Hot position just above the Exhaust Header, to a much cooler position over at the fender wall just below the hood hinge. It's pretty much common knowledge that electronic voltage regulators do not last long when mounted near any source of extreme heat.

Wiring Harness Splice Location

Relay mounted on fender wall near battery

Perfect output at gage

VR relocated to fender wall.

Well, I can't afford keep replacing VR's every other thing, so I had to do something about this little problem.

As I suspected, there were so many shorts and bad connections in old the electrical system, due to old dirty connections & connectors, that it was reducing the voltage to the VR, causing it to remain in an active state all the time, which is why the cheap over the counter units were frying on a fairly frequent basis. Even a heavy duty Transpo unit held out for as long as it could, but eventually lost the battle.

That said, I decided to install a Relay in the system that would relocate the voltage sensing circuit of the VR from the weak (under voltage) ignition circuit, and move it directly to the Battery.

To do this I had to locate the main ignition circuit splice in the wiring harness. Then locate and separate the two required charging circuit wires from the splice, and wire them to the relay as illustrated below. I ran the wires through the wiring harness to keep it neat. Then I ran a seperate hot and ground from the relay to the battery. Problem solved...

The gage for the Charging System holds steady at dead center now. This is the first time since I've owned the truck that the gage has read correctly. Previously it had always leaned more to the charging side, sometimes more than others, but always to the charging side. As you might expect, the battery would often get quite warm as well.

I eventually got in there and took care of all those pesky electrical connections that were drawing down on the system, and causing erratic behavior issues, so that's all good to go now as well.

I also relocated my VR from the OEM Death Valley Hot position just above the Exhaust Header, to a much cooler position over at the fender wall just below the hood hinge. It's pretty much common knowledge that electronic voltage regulators do not last long when mounted near any source of extreme heat.

Wiring Harness Splice Location

Relay mounted on fender wall near battery

Perfect output at gage

VR relocated to fender wall.

Last edited:

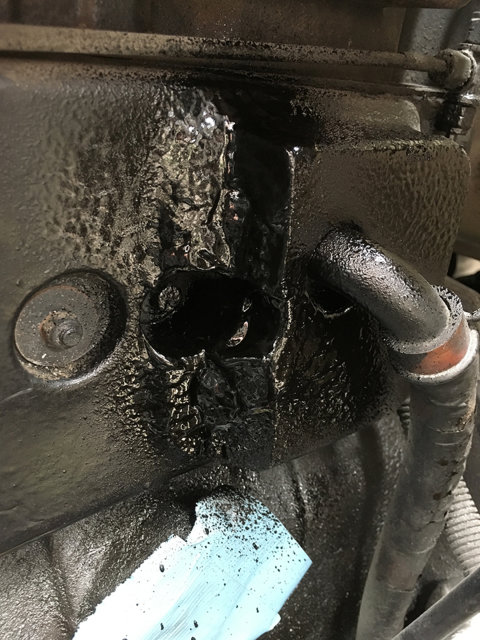

So it was about mid April that I decided it was time for an oil change. After performing said oil & filter change I fired up the truck and started looking around for any leaking oil. Well I found a leak, but it wasn't engine oil, it was diesel fuel... Crap!

Well, I tracked the leak down, and it was in the absolute worst spot possible... the inboard side of the VE fuel injection pump. The O-ring for the little flange opposite the KSB had apparently blown out. There's only one way to get that fixed... strip the entire left side of the block down and pull the pump. Much easier said than done when it has been sitting there for the last 30 years.

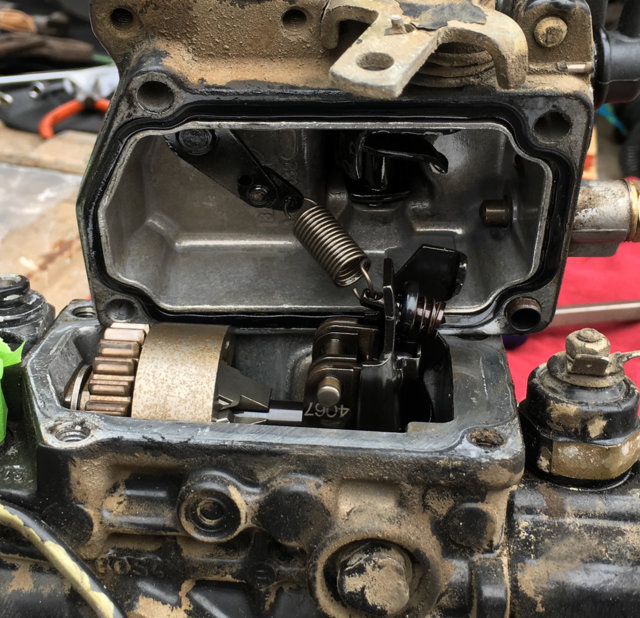

Anywho...That's just what I did! Since I had the VE pump off sitting on the bench, I figured there would never be a better time to make a couple of changes here as well. That said, I swapped out the original governor spring for a 3200 RPM job, and a better fuel pin too.

Blown Ring

Old Fuel Pin being removed

Governor Spring swap

Ready to go back in

Well, I tracked the leak down, and it was in the absolute worst spot possible... the inboard side of the VE fuel injection pump. The O-ring for the little flange opposite the KSB had apparently blown out. There's only one way to get that fixed... strip the entire left side of the block down and pull the pump. Much easier said than done when it has been sitting there for the last 30 years.

Anywho...That's just what I did! Since I had the VE pump off sitting on the bench, I figured there would never be a better time to make a couple of changes here as well. That said, I swapped out the original governor spring for a 3200 RPM job, and a better fuel pin too.

Blown Ring

Old Fuel Pin being removed

Governor Spring swap

Ready to go back in

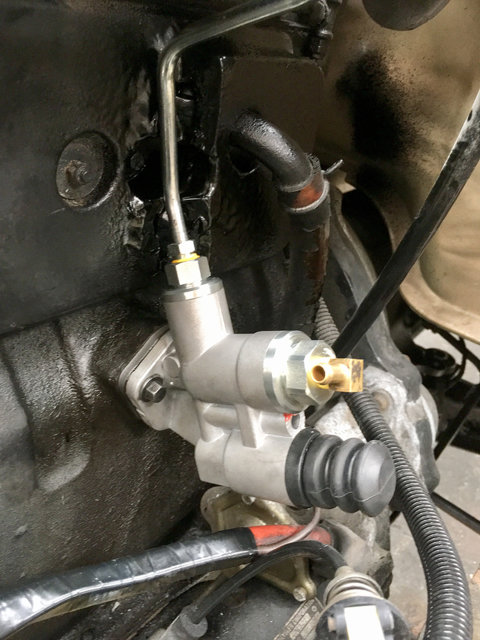

Since I now had the VE pump and all it's associated hardware stripped off the drivers side of the block, I figured now would be a good time to loose the old OEM Diaphragm fuel pump and install that fancy updated HVLP fuel pump I picked up from Mark over at Dieseltuff.com. Essentially, a 2nd Gen pump modified for 1st Gen use.

Had to break out the trusty Dremel tool and nip the corners of the sound deadening plate to make room for the new fuel line that comes with the pump, but that was no effort. After I test fit the new pump and tubing I pulled it off and sprayed some of that cheap rubberized Boom Mat coating over the area where I had removed the sound dampening. Did I have too, no, but it looks nicer now, and it's sealed up again.

After that I mounted the pump and hooked everything back up, installed a new Fleetguard Fuel Filter.

Two priming strokes from the new pump and I had fuel gushing out of the outlet side of the fuel filter... Good Pump.

This was by far the best upgrade I have performed to date, hands down! What a difference!

The old OEM Diaphragm Pumps put out minimal pressure at idle and lower RPM, but they put out "Zero" pressure at WOT. Consequently, you've always got your foot in it when climbing hills, etc with these 89-90 1st Gen Cummins. These modified 2nd Gen HVLP pumps that Mark carries put out 14 PSI around town and 4 to 5 PSI at WOT.

That said, my old 1st Gen drives just like any other vehicle in my yard now. Just press the pedal and your gone brother.

Had to break out the trusty Dremel tool and nip the corners of the sound deadening plate to make room for the new fuel line that comes with the pump, but that was no effort. After I test fit the new pump and tubing I pulled it off and sprayed some of that cheap rubberized Boom Mat coating over the area where I had removed the sound dampening. Did I have too, no, but it looks nicer now, and it's sealed up again.

After that I mounted the pump and hooked everything back up, installed a new Fleetguard Fuel Filter.

Two priming strokes from the new pump and I had fuel gushing out of the outlet side of the fuel filter... Good Pump.

This was by far the best upgrade I have performed to date, hands down! What a difference!

The old OEM Diaphragm Pumps put out minimal pressure at idle and lower RPM, but they put out "Zero" pressure at WOT. Consequently, you've always got your foot in it when climbing hills, etc with these 89-90 1st Gen Cummins. These modified 2nd Gen HVLP pumps that Mark carries put out 14 PSI around town and 4 to 5 PSI at WOT.

That said, my old 1st Gen drives just like any other vehicle in my yard now. Just press the pedal and your gone brother.

Last edited:

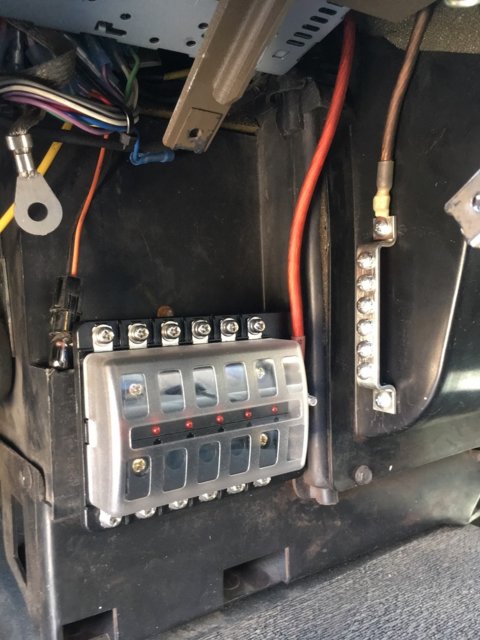

After that I added an Aux Fuse Panel and Ground Bus with a couple of 10 gauge cables, for accessory items like extra gages or whatever. I located it out in the open down at the heater box for ease of access and visual inspection.

It wasn't to long after that, just recently in fact, that I started having some issues with the steering. I didn't see anything obvious when performing the usual checks, but still, the steering was getting real funky, bad enough that I had to finally take it off the road.

I decided the best thing to do in this case was to simply tear it all down, right down to the king pins, so I did. In the process I discovered a number of deficiencies that were definitely attributing to the problem, but the biggest one, the real culprit, turned out to be a half frozen steering knuckle on the drivers side. One side of the universal joint was fine, but the other side had finally frozen up tight. So tight in fact, that it had to be burned out with a torch.

I decided the best thing to do in this case was to simply tear it all down, right down to the king pins, so I did. In the process I discovered a number of deficiencies that were definitely attributing to the problem, but the biggest one, the real culprit, turned out to be a half frozen steering knuckle on the drivers side. One side of the universal joint was fine, but the other side had finally frozen up tight. So tight in fact, that it had to be burned out with a torch.

Long story short... I replaced everything up front including the King Pin assemblies... new Rotors, Calipers, Steering Gear, new Borgenson Steering Shaft, Bilstein Shocks the works. The only thing I didn't replace was the wheel bearings; they had been replaced previously by the PO and looked just fine.

My only regret here is I should have bought a RedHead Steering Gear. I didn't have the money for a RedHead at the time so I picked up an AC Delco reman job instead. Picked it up and installed it on the truck in a hurry without bench checking it first. Spent the next week or two adjusting it in place. Almost perfect now, but still tweaking it.

I kept the original though... I'll rebuild it at a later date. It was okay anyway, just needed a new seal at the input shaft really.

My only regret here is I should have bought a RedHead Steering Gear. I didn't have the money for a RedHead at the time so I picked up an AC Delco reman job instead. Picked it up and installed it on the truck in a hurry without bench checking it first. Spent the next week or two adjusting it in place. Almost perfect now, but still tweaking it.

I kept the original though... I'll rebuild it at a later date. It was okay anyway, just needed a new seal at the input shaft really.

Last edited:

installed a couple of simple suspension upgrades on Montana last week

I added a Roadmaster Active Suspension kit out back, and a heavy duty 1.125" ADDCO sway bar up front. I liked the fact that the truck was already setup for a sway bar, predrilled and tabbed, ready to go. It made for an easy nut & bolt install!

I added a Roadmaster Active Suspension kit out back, and a heavy duty 1.125" ADDCO sway bar up front. I liked the fact that the truck was already setup for a sway bar, predrilled and tabbed, ready to go. It made for an easy nut & bolt install!